|

Eugene Dakin Ph.D., P.Chem Professional Chemist |

|

|

|

|

Foamer Chemistry Foamers are great at removing water from wells which maximizes well production. Foamers are usually used when excess water or condensate is produced with a low pressure well. The following diagrams show the difference between a non-producing well without a foamer, and a producing well with a foamer.

There are many different types of foamers. Each type is designed for a specific type of well.

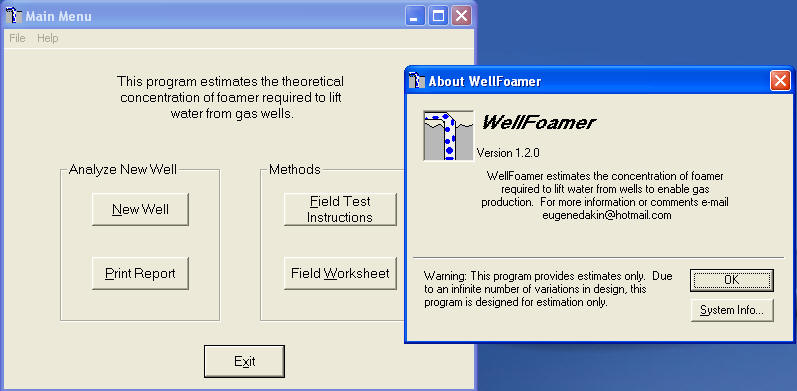

The following program has been developed for certain Oilfield Companies, and is not available to the general public. The following screen shot shows a few details of the program.

There are many considerations that need to be determined before implementing a foaming program. The above information is for general informational use only.

Considerations required for selecting the proper foamer and implementing a foaming program are:

1) Concentration of condensates 2) Distance between well and separator (fast-crash ability) 3) Salt concentration (Sodium, Calcium, et al) 4) Potential production rates 5) Foamer injection rate 6) Oil/water separation parameters 7) Production string length 8) Foamer freeze point (winter months)

|

|

| © 2006 - Eugene Dakin -

|